Race Car Hauler, Cheap-Style: Black Iron Racing’s Box Truck 2.0

[Editor’s Note: Chris Floren (aka CFlo) from Black Iron Racing and co-founder of Daily Turismo—who races this magnificent beast—wanted to share details of his box-truck race car hauler. We are happy to share his work]

Race cars get a deserved amount of glory in the 24 Hours of Lemons, but what about those unsung heroes of the paddock, the support vehicles? Trucks, trailers, vans, converted buses, Volvo wagons, early ‘60s proto-SUVs…You name it, chances are a Lemons team figured out how to tow their race car with it. The Lemons paddock’s race car hauler in no small part cultivates the “Burning Man meets circle track” atmosphere. And one of those defining vehicles is this unassuming-but-magnificent box truck.

Historically, my team (Black Iron Racing) borrowed an open trailer for each race. We made do with standard open-deck rentals, a converted Jet Ski trailer bought from an ex-Kawasaki employee, and even the occasional development mule trailer normally laden with water tanks and scrap iron castings for diesel truck durability testing, borrowed from our employer. We explored our inner desert-rat tendencies by renting a toy hauler for the one and only Chuckwalla race in 2012.

After that experience, however, we were itching for something kookier. In 2014, we took a hard look at box trucks. We had some experience with one, having been exposed years earlier by Alex Vendler of the Geo MetroGnome and its mothership the G.T. (Gnome Transporter) – the original Lemons Box Truck. Alex was the trailblazer in this arena. After borrowing his race car hauler for a few local races we thought, “Hey, if Vendler can do it, why can’t we?”

If only…

Meeting BIRT

Locating a used box truck in the Los Angeles area is incredibly easy, as Vendler explained in his original MotoIQ article. The market included van-cab trucks, pickup-cab trucks, and endless variety in box length, condition, and price. That market was flooded with trucks about to be rendered obsolete or require an upgrade to stay on the road. Thanks, CARB Truck & Bus Regulation here in California! Great for clean air; not so nice for truck owners.

We settled on a truck from craigslist (Where else?) that was a former Sara Lee bread-dough delivery truck. We instantly christened it BIRT (Black Iron Racing Transporter). BIRT is a 1995 International 4700 LPX. That is the Lo-Profile model with a lower ride height, smaller tires, and most importantly a handy lower box-load floor for ease of race car crammage.

Our fleet-maintained truck came with Penske service history and the International T444E diesel V8. This is the low-power cousin to the 7.3L PowerStroke as found in Ford Super Duty pickups of the late ‘90s to early 2000s. Since it was about to turn 20 years old when we bought it, it needed an engine swap to stay legally registered as a commercial truck in California. The seller explained that most of his customers were re-registering these older trucks in Arizona. These guys were running Arizona plates but physically keeping the vehicles in So-Cal.

How hard could it be?

The legality of that solution seemed a bit suspect to us. And we definitely weren’t going to buy a mega-buck 2010+ medium-duty common rail diesel engine with all of its expensive exhaust-aftertreatment equipment. So what to do? Turns out Vendler’s G.T. template had the answer again: Convert the truck into an RV. By making a few changes inside the box, slapping “NOT FOR HIRE” stickers on the doors, and going through a DMV inspection, we could get regular passenger vehicle plates on this bad boy. That would reduce registration and insurance costs. Most importantly, it rendered the”RV” exempt from smog and legal to drive with the original 1995 7.3-liter engine belching smoke and oil.

This all sounds amazing, but mainly we followed Vendler’s lead here. We learned a few valuable lessons of our own along the way. In case you have similarly obtuse thoughts about race-car hauling, here are our thoughts on a box-truck race car hauler.

1. Be Persistent When Converting your Truck.

The California DMV’s role in RV or motorhome conversion can be drawn-out and frustrating. Keep at it and you’ll avoid lots of commercial vehicle specific costs and complexities over the truck’s life. Other states’ processes may be more logical or even unnecessary. Arizona’s MVD, for example, says trucks at 26,000 lb GVWR or less do not need a U.S. DOT number if not being used in interstate commerce. Arizona also allows the owner to declare the gross weight. The owner might declare a lower max weight—maybe the truck’s unladen weight plus 5,000 lb of race car, tools, and parts—to save some coin. Do some research in your home state to find helpful tricks like this.

The physical modifications for RV conversion were straightforward enough. We built a simple wooden workbench out of old doors in the front of the box. We mounted a small used RV-spec sink and a standard home microwave. For plumbing, we hooked up a legit RV sink pump, an $80 pressure-regulating Shurflo (originally bought for water injection on a Dodge Daytona Shelby Turbo), a switch, and two 5-gallon buckets of water (one clean and one “gray”).

To power the microwave, dorm fridge, and any other home appliances, we screwed a 110-volt AC inverter to the underside of the bench. That hooked up to the truck’s stock dual-battery setup under the cab. For sleeping quarters, we made a rudimentary bunk out of plywood and 2x4s carriage-bolted through the box wall. The wall is some kind of neat wood/fiberglass composite That makes it easy to work with, but you need to think about spreading the load properly! For heat, we strapped in a simple propane-powered radiant burner. We technically met the bare minimum requirements for an RV conversion, per the letter of the law.

When it came time to prove our mettle and get the vehicle reclassified, local DMV employees took one look and immediately shook their unkempt state clerk drudgeon heads in unison. “No, this is not an RV. An RV must have windows,” they said in slightly robotic voices.

“But look,” I said, “right here in the CA vehicle code’s definition of an RV or motorhome, there isn’t any requirement for even one window.”

No matter, that only exacerbated their sour moods. They instinctively sensed funny business because of the sparse industrial look of our self-made RV. The roll-up doors and the hydraulic lift gate didn’t help. They probably assumed we were going to keep using this thing as a commercial truck to dodge registration fees. They expressed a valid but maddening concern, especially when we were following the letter of the law.

So we tried again. Turns out, a friendly and helpful employee at another DMV across town was very satisfied with our work. They signed off without too many questions nor bribes of any kind! [Editor’s note: We don’t encourage anyone to bribe public officials for real.] If you to attempt this yourself, I’d suggest being as polite as possible. Describe the truck as a “personal toy hauler” to any DMV or insurance company employee. They will be familiar with this term, which may help alleviate concerns about the big door in the back. And the fact that your “RV” looks suspiciously like a box truck.

The physical work of converting the truck to RV spec was easy and quick – we finished that in a weekend. But the paperwork took a month or more. Stick to it; the race car hauler benefits are worth the headache.

2. Make Some Solid Ramps.

It’s tempting to roll down to a local discount tool emporium to buy a $100 set of ATV ramps. That will get your crapcan race car loaded into your crapcan box truck. Trust me, that’s what we did! Two sets, actually. But this is not the best plan. In theory, our system is a good one.

However, the execution needs work. We have one long set of folding steel ramps that locks into the truck bed on one end and then a big ¾” hole drilled in the other end. Our second set of ramps are straight, also steel, with some plates welded to the upper ends with matching holes drilled. A set of old MR2 strut shafts (high quality chrome!) act as pins between the two sets of ramps. Each pin is supported by two beefy jackstands. The end result is long and packs up fairly compact when not in use.

The problem with our system is stiffness. We aren’t exceeding the load capacity of any single ramp in use. Our car weighs about 2,800 pounds if we have to guess, and each ramp only supports one wheel at a time, so call it 700 – 800-pound max point load. The problem is repeated abuse of cheap steel structures. They eventually flex enough to taco inward on themselves and lose some crucial bending stiffness. Every time we load or unload the car, we cycle the ramps again. They have started to make some terrible noises.

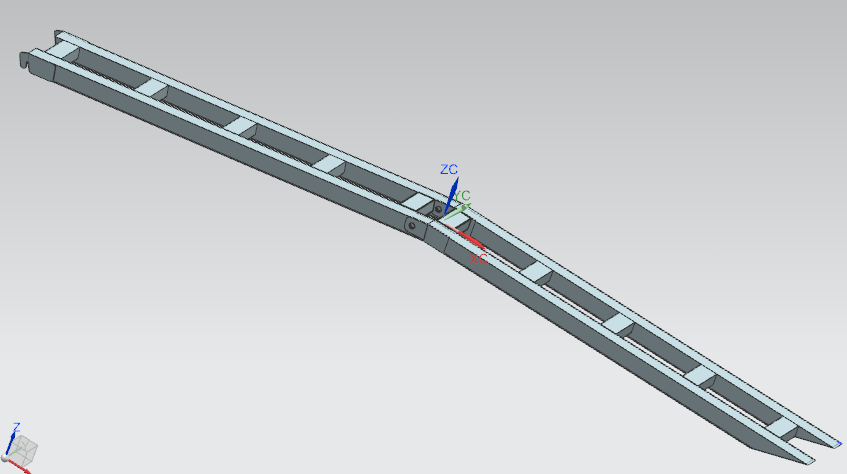

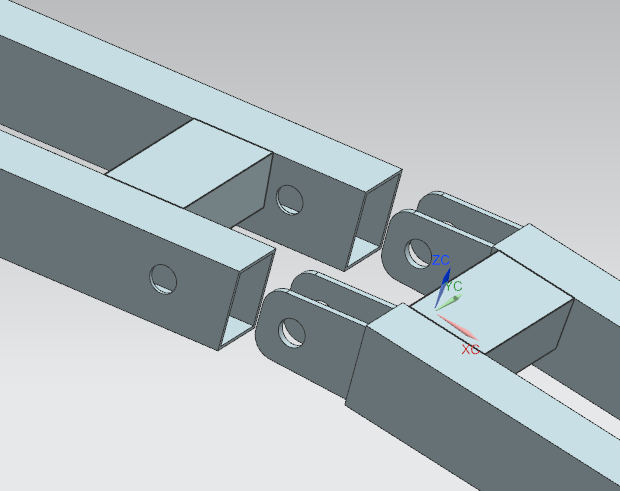

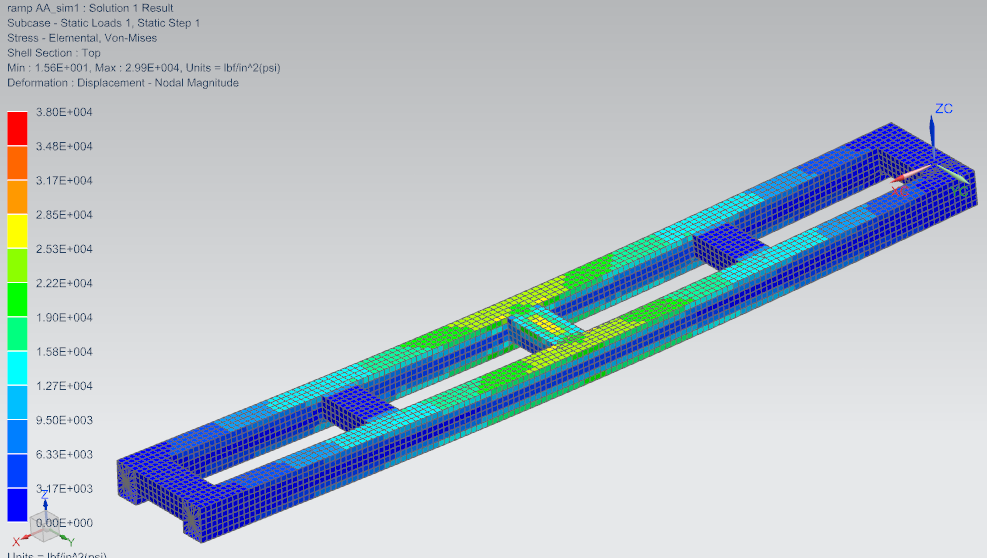

The right way? Make or buy some beefy ramps with enough cross-section height to support the car’s weight. One of our buddies designed this nice aluminum system for us. He ran some quick-and-dirty FEA to validate the strength and stiffness. Materials cost would be about $300 using square aluminum tubing. That doesn’t count labor to cut and weld it all together, of course, which would be money well spent given the sketchiness of our only slightly cheaper ramp setup. Steel would be cheaper, stiffer, and heavier given the same dimensions. We’d go with aluminum just to make setup easier and reduce weight that the truck has to carry.

Another piece of advice – make sure the race car hauler ramps lock solidly into the truck box or frame. Use some kind of hinges, lock pins, or tabs. Some 3/8” bolts vaguely acting as vertical pins drifting around in poorly drilled holes doesn’t quite cut it.

3. Install a Big Beefy Winch.

Again, ATV parts are not the answer. We had a light-duty winch that was technically rated high enough to pull any of our cars. However, for BIRT we sprung for a 10,000-pound Harbor Freight Badlands winch and bolted it through the floor near the front of the box. When we’re feeling adventurous we can drive the race car up the ramps in one smooth motion. When we’re being a bit more responsible (or the car is broken), the winch makes fairly quick work of dragging it into the box.

It may be common sense, but please make sure to bolt this to a structurally sound piece of your truck. Make sure to wire the winch directly to the batteries with heavy gauge cable, too. A system of hand signals for communication between winch operator and steersperson in the car is another good idea since these winches are loud enough to make verbal cues hard to hear. Learn and follow proper winch safety procedures and treat it with some respect, almost as if your heavy-ass race car is dangling from the end of its cable.

The wrong way to pack

4. The Race Car should be the Last Thing In.

It pays to think about how the tools, parts, and car are loaded into and out of the race car hauler. A race weekend sees at least four loading or unloading events. That makes a lot of shuffling around of heavy stuff if you don’t have a semi-logical plan in place. For the first few years with BIRT, we loaded the race car first, then jammed all of our spare wheels, parts bins, jack stands, welder, and stuff in the open space around it.

This system offers the benefit that, theoretically, packing the floor solid with stuff reduces cargo shifting around while the truck bumps down the highway. In practice, the car, parts, and loose items always move a bit. Instead of this labor-intensive and frustrating system, I’d suggest making dedicated storage areas for everything. Get your stuff loaded into the box while the car is still circulating around the track on Sunday afternoon. Make the car itself the last thing in. You put the ramps away, close and lock the door, and your race car hauler is off.

We typically bring a whole car’s worth of spare suspension parts, like control arms, dampers, uprights, axles, brakes, wheels, and tires. That’s a lot of heavy stuff to move – so if possible, make some under-slung storage containers or steel lockers that secure all of these dense and bulky parts nicely under the box. You could access these compartments via hatches in the floor or dedicated doors on the outside (similar to the luggage compartments under a coach bus or school bus). This helps keep the truck’s center of gravity as low as possible. More importantly, it means you don’t have to move until it’s time to break them out for emergency race car repairs.

For wheels and tires, bolt a simple rack to the box wall up high over the hood. We used steel tube racks salvaged from a local hybrid-luxury carmaker that went belly-up. I shortened one of the racks, then welded some flat rectangular steel tube supports into the rail system on the box’s inside wall. Now, we can leave those in place too while the car gets loaded or unloaded. The hood of the race car tucks under the rack, so a bit of measurement was needed to make sure we wouldn’t crash the windshield into steel tubing.

The other recent addition was a solid steel shelf on the front wall above the main workbench. With a bit of EMT conduit, I made some shelf supports to hang it securely. I added a little steel fence to keep all of our oil bottles and other fluids stored nicely but easily accessible. I’d love to keep going with cabinets and shelves in the box, but for now it’s pretty nice.

5. Cheap LEDs Everywhere!

This isn’t much a stretch these days since LEDs are so cheap and ubiquitous. Early on, we ran a long string of the super-cheapy strip LEDs around the ceiling. This is the type that doesn’t even have a housing and just sticks onto any hard surface. After living with this for a few years, I’d say we could safely triple or quadruple the amount of lighting, especially near the back of the box and on the inside of the roll-up door somehow. A few spotlights on the back exterior would make night loading a breeze. But we haven’t gotten around to that upgrade yet either.

6. Get a Roadside Service Plan, with Towing Coverage

Talk about a drag, try getting stranded with a broken race car hauler a few hundred miles from anywhere. Then realize that the AAA RV coverage people do not, in fact, get very excited about towing a former commercial box truck registered as an RV. This medium-duty truck requires a big monster tow vehicle to move with the huge hydraulic boom and about 50 tires (above). Those guys aren’t cheap. Figure this stuff out first, because chances are pretty good that your cheap used-bread delivery vehicle will have some kind of breakdown and need a tow during its new career as a heavily loaded long distance race car hauler.

7. Regular Maintenance is Your Friend.

The International T444E 7.3L V8 in our truck has a nifty HEUI fuel system, in which fuel pressure is multiplied inside each injector via a 7:1 piston that is in turn driven by a high-pressure oil system. This is fed by the standard oil pump down in the engine block. That has its own reservoir, high-pressure pump, regulator, pressure sensors, lines, ad nauseam. So many opportunities to learn how to troubleshoot!

Other older purely mechanical diesel engines may have simpler Bosch P-pumps or similar. Either way, it pays to read up on diesel mechanics and perform some regular maintenance on the system. Even if you have a big-block gasoline V8, get in the habit of changing oil, filters, belts, hoses, and any other consumables on a regular basis. Not only is the maintenance itself good for your engine, but it gives you a chance to poke around and find any new leaks or other fun issues that aren’t obvious…yet.

The whole race weekend hinges on the reliability of the race car hauler. If the box truck breaks down on the way, your easygoing fun hobby activity just turned into a roadside hellscape of busted knuckles and long phone calls. Lots of common issues are preventable if the vehicle has a mechanic who regularly checks it over. Since you’re on a Lemons budget, that may as well be you.

8. Check your Truck’s Tires.

With the BIRT, tires have been no issue at all. We are still a bit shell-shocked from Alex Vendler’s old Gnome Transporter. The G.T. seemed to have a blowout on just about every trip. I think we lucked out by finding a truck with good quality commercial tires that weren’t past their expiration date. You should attempt to do the same! If in doubt, replace a tire or two before the maiden long journey. Check pressures every time, and have a game plan ready when a tire ruptures or throws a tread. If there’s no way to easily change a tire by the side of the road, make sure your roadside-assistance coverage includes tires.

9. Earmuffs!

An old cheap commercial diesel truck is not a modern luxury SUV. Noise, vibration, and harshness will be on par with your Lemons racer itself. Race car hauler driving duties tend to rotate between our team members. Most of us wear a big pair of earmuffs while driving to keep sanity in check. The noise level isn’t particularly deafening at first. However, after 8 hours in the cab, it can really wear on the old brain stem.

Some sort of music-playing arrangement helps a lot here, too. If you’re feeling opulent, invest a few hours and dollars into installing sound deadening in the cab, around the floor and firewall especially. Working air conditioning is another awesome perk if you can manage it. It improves climate control, but it also reduces noise by being able to roll up the windows on the highway.

10. Insurance is A Thing.

You might think obtaining RV insurance for a former commercial truck would be a breeze, but that was a big pain too. As the truck’s legal owner, teammate Dan churned through about half-dozen companies—including some in-person inspectors—before giving up and paying the 10-times-higher rate for commercial insurance for the first couple of years.

Part of the healing process was later joining up with an insurance “brokerage.” That is just a middleman who makes a commission on the policies but also knows insider tricks to make up the difference. It took a new dude that was doing an annual checkup on BIRT’s policy to finally find a company willing to insure it as an RV for about $150 per year instead of the exorbitant $1,100 annual rate the other guys charged. Shop around and get cozy with a broker.

Box it

Without a box truck, you’re just another schmoe who tows. With a box truck, you’re flying at 70mph down the highway (no California towing speed limit, suckers!) with the race car safely hidden in the back. And you look like a boss in the process.

Once set up at the track, you’ve got a home away from home and a mobile workshop with shelter. Add a generator and you’re a power source. A MIG welder makes you a resource. Add some boxbeats and disco lights: You’re a party source. It adds a whole new dimension to the Lemons team experience, but the perils and particulars of box truck ownership might just pay off…if you’re smarter than us!